Every workplace, no matter how safe it seems, has its risks. From construction sites to cosy office cubicles, accidents still manage to sneak through. A misplaced cable, a wet floor, a worn-out machine part — all it takes is one tiny oversight. And suddenly, someone’s hurt. Productivity drops. People start whispering about safety. Questions fly.

But here’s the thing. What happens after an accident matters even more than the accident itself. That’s where effective accident investigations come in. They don’t just explain what went wrong — they help stop it from happening again. When done right, they turn chaos into clarity and prevent future mishaps from becoming part of the routine.

Let’s dive into how.

Understanding the True Cost of Workplace Accidents

Most people see an accident and think about the injury — the bruised arm, the twisted ankle, the trip to A&E. But there’s a lot more going on behind the scenes.

There’s the obvious stuff: sick pay, insurance paperwork, downtime. Then there’s the not-so-obvious: missed deadlines, shaken-up teammates, managers scrambling to fill the gap. If the injury’s serious, the HSE might step in. That can lead to investigations, penalties, or even legal action. It’s not just money — it’s time, trust, and morale.

And don’t forget the impact on the injured person. It’s not just physical pain. It’s time off work, stress, frustration, maybe even a long-term struggle to return to normal. One incident can ripple across the entire business.

The real kicker? Most accidents are avoidable. That’s why understanding what went wrong is so important.

The Critical First Step: Building Investigative Competence

Here’s a harsh truth: Many workplace accidents get brushed off. Someone writes a quick report, files it away, and calls it a day. No deep dive. No real answers. No change.

But effective accident investigations? They dig deeper. They ask why something happened, not just what. And they don’t stop at human error. They look at training, equipment, lighting, layout — the whole picture.

To get this right, businesses need people who know how to investigate properly. That’s where Online Accident Investigation Training comes in. It helps them understand root causes—not just obvious slip-ups. And when everyone’s on the same page, investigations stop being a paper exercise. They become a powerful tool for change.

It’s not about pointing fingers. It’s about asking the right questions and making things better.

The Anatomy of a Successful Investigation

Not all investigations are created equal. The best ones follow a clear process. It’s not rocket science — but it does take a bit of discipline.

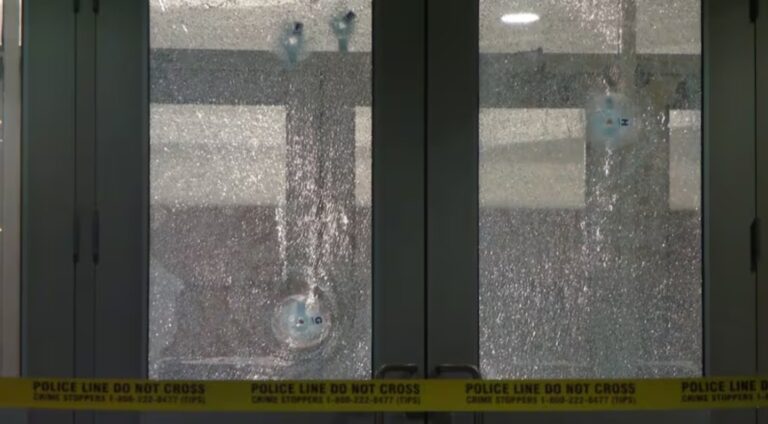

First up is the immediate response. Make the area safe. Get help if someone’s hurt. Secure the scene. Then, it’s time to start gathering the facts. Take photos. Collect damaged equipment. Write down everything that stands out. Memories fade, but details matter.

Next: talk to people. Not just the person involved, but anyone nearby. Ask open-ended questions. What did they see? Hear? Smell? Often, little things come out that make a big difference.

Then comes the analysis. Use tools like the ‘5 Whys’ or a fishbone diagram. Keep asking why until the root cause pops up. It might be a broken part. Or a training gap. Or a process no one’s updated in years.

Finally, put it all together in a clear report. Lay out what happened, why it happened, and what needs to change. No fluff. No blame games. Just honest, useful insight.

Turning Lessons into Lasting Change

An investigation’s only useful if it leads somewhere. A shiny report that gets buried in a folder? That won’t stop the next accident.

The real magic happens when lessons get turned into action. Maybe it’s replacing a faulty gear. Maybe it’s updating a risk assessment. Maybe it’s scrapping an old habit that’s quietly dangerous. Whatever it is, it needs to happen — fast.

And don’t keep it a secret. Share findings with the team. Not the boring details, just what matters. Let them know what went wrong and how it’s being fixed. People are more careful when they understand the ‘why’ behind safety rules.

Better yet, feed those insights into staff training. Add real examples to inductions. Use incidents as teaching tools, not scary stories. Over time, small changes build a stronger safety net — one that actually catches things before they fall apart.

Prevention Beyond Policy: Safety That Sticks

Rules are good. Every workplace needs them. But rules alone don’t make people safe — habits do. And habits come from culture.

A strong safety culture isn’t built overnight. It grows when people look out for each other, when near-misses are reported, not hidden. When leaders walk the talk, not just talk the talk. It’s the difference between ticking boxes and truly caring.

Blame-free reporting helps, too. If staff think they’ll get punished for admitting mistakes, they’ll stay quiet. And silence is dangerous. The more people speak up about wobbly ladders, broken guards and leaky pipes, the more chances there are to fix things before someone gets hurt.

Real prevention comes from the ground up. It’s in toolbox talks, quick check-ins, and people feeling safe enough to say, “That doesn’t look right.”

The Role of Immediate Response in Mitigating Harm

When an accident happens, time is everything. The faster someone reacts, the better the outcome. That’s why first aid isn’t just a nice-to-have — it’s a must.

Cuts, burns, trips, even serious injuries — all of them need quick attention. If someone on-site knows what to do, they can ease the pain, prevent things from getting worse, and even save a life.

That’s where basic first aid at work comes in. It’s not just for major emergencies. It’s knowing how to stop bleeding, treat a sprain, and help someone in shock. Simple steps, but they make a big difference.

First aid also helps preserve the scene. A trained responder can stabilise the injured person without disturbing important evidence. That helps the investigation later. And it keeps everyone calm, because panic solves nothing.

UK law is clear about this. Workplaces must have first aid kits and enough trained staff to handle emergencies. It’s not just ticking off a regulation — it’s about being ready when the worst happens.

Measuring Success and Staying on Track

So, how do you know if investigations are working? One sign: fewer accidents. Another: better reporting. When people feel confident that their concerns will lead to real change, they speak up more.

Look at trends. Are the same issues popping up again and again? If so, something’s being missed. Regular reviews help keep control measures fresh and focused.

Don’t forget to track follow-up actions. It’s easy to write a recommendation. It’s harder to make sure it actually happens. Set deadlines. Assign responsibility. Then go back and check.

Success isn’t about perfection — it’s about progress. Every lesson learned, every hazard spotted early, and every injury prevented is a step in the right direction.

Conclusion: Dig Deep, Act Fast, Stay Safe

Workplace safety isn’t luck. It’s the result of choices — what’s reported, how it’s investigated, and what’s done next. A solid investigation digs beneath the surface. It asks the awkward questions. It challenges assumptions.

The goal isn’t to find fault. It’s to find answers — and use them. From spotting weak spots to building stronger systems, effective investigations stop history from repeating itself.

And when quick action meets lasting change, the whole team benefits. Fewer injuries. Fewer interruptions. More peace of mind.

That’s the power of doing it right — not just once, but every time.